Technical

Information

Technical Information

Newlay Walling Stone is manufactured from a carefully controlled mixture of graded limestone and other natural aggregates, cement and pigments, in accordance with European BS EN 771-5 product standards for manufactured stone masonry units. They meet the statutory requirements of the relevant section of The Building Regulation 2010 with amendments and The Building (Scotland) Regulations 2004 with amendments.

All Newlay Walling Stone manufacturing facilities are BSI registered and operate to the requirements of BS EN ISO 9001:2008 and BS EN ISO 14001:2004 – the national and international standards for quality and environmental management systems.

Thermal Conductivity:

1.0 W/mK (λ10, dry, unit, S1) Based on table value from BS EN 1745:2012 p=50%

Gross Dry Density:

2000 Kg/m3

Compressive Strength:

Mean 20N/mm2 (Normalised)

Perpendicular to bed face Coverage:

Dependent on the combination of units chosen

Fire Resistance:

Euroclass A1

Dimensional Stability:

0.41mm/m Tested to BS EN 772-14:2002

Water Absorption:

<9g/m2.s Tested to BS EN 772-11:2011

| Essential characteristics | Performance values |

|---|---|

| Dimensions | Length: 225mm, 300mm, 450mm |

| Width: 100mm | |

| Height: 140mm | |

| Tolerance Cat: D1 (+3/-5mm) | |

| Configuration of units | Group 1 to EN1996-1-1 |

| Compressive strength | Mean 20N/mm² perpendicular to bed face |

| Dimensional stability | 0.40mm/m |

| Bond strength | 0.15N/mm² |

| Reaction to fire | Euroclass A1 |

| Water absorption | <3.0g/m²/s |

| Water vapor permeability | 5/15μ (Tabulated value) |

| Direct airborne sound insulation | Gross dry density 2000kg/m³ |

| Thermal conductivity/resistance | 1 W/mK(λ10,dry,unit S1) |

| Durability against freeze-thaw | For external use |

Suggested Load Make Up

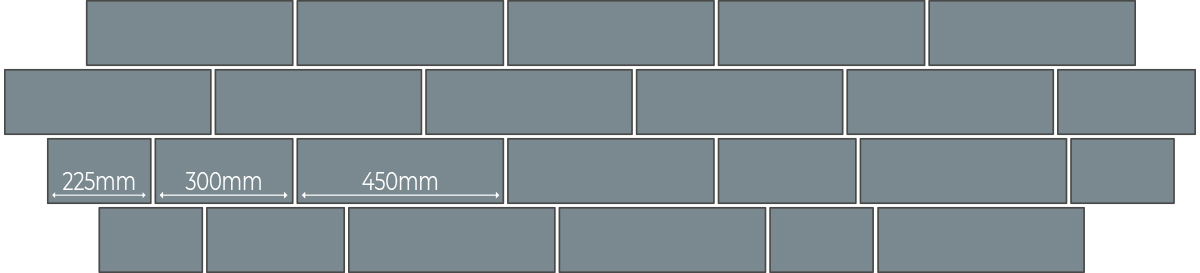

This pattern is achieved by using the same course height 140mm and laying in three different lengths in a stretcher bond style as detailed in the table below. (The following is for guidance only).

| Course Heights (mm) | Length (mm) | Pieces per pack | Blocks / m2/ | m2/ / Pack | Pack Weights |

|---|---|---|---|---|---|

| 140mm | 225 | 160 | 28.4 | 5.64 | 1072 |

| 140mm | 300 | 120 | 21.5 | 5.58 | 1060 |

| 140mm | 450 | 80 | 14.5 | 5.52 | 1049 |

Bond Patterns

In order to create a natural, traditionally laid stone effect there is a tendency to want to create a ‘random bond’.

Newlay Calder Walling Stone is available in three course lengths to help create this and the following are suggestions of bond patterns that can be used.

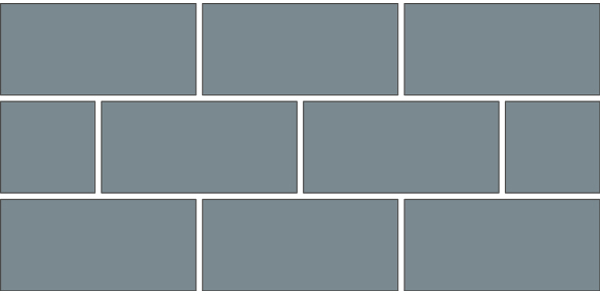

300mm BOND

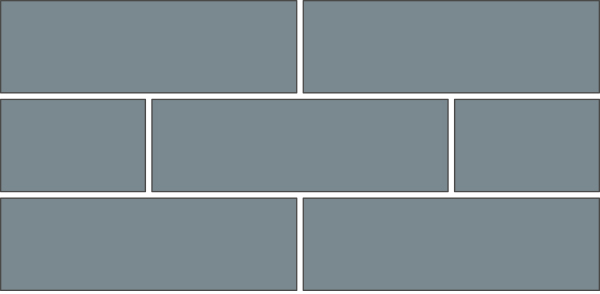

450mm BOND

RANDOM BOND

All 140mm course using 3 lengths. The random pattern is a guide only in the ratio of 60:30:10 for 450:300:225 lengths